Knowridge

2w

272

Image Credit: Knowridge

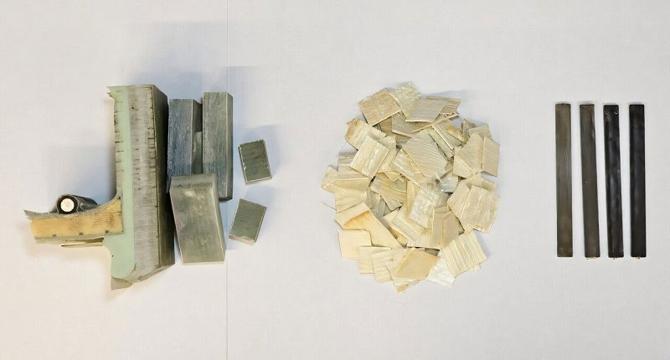

Scientists find way to turn old wind turbine blades into stronger plastics

- A team of researchers at Washington State University has developed a cleaner and simpler way to recycle wind turbine blades.

- The new recycling method breaks down the glass fiber-reinforced polymer (GFRP) material of the blades using superheated water and a mild chemical called zinc acetate.

- The process successfully recovers both the glass fibers and the resin material, which are then added to other plastics, making them more than three times stronger and over eight times stiffer.

- The recycling method is cost-effective, environmentally friendly, and offers a solution to the growing waste problem of retired wind turbine blades.

Read Full Article

16 Likes

For uninterrupted reading, download the app