Brighter Side of News

1M

311

Image Credit: Brighter Side of News

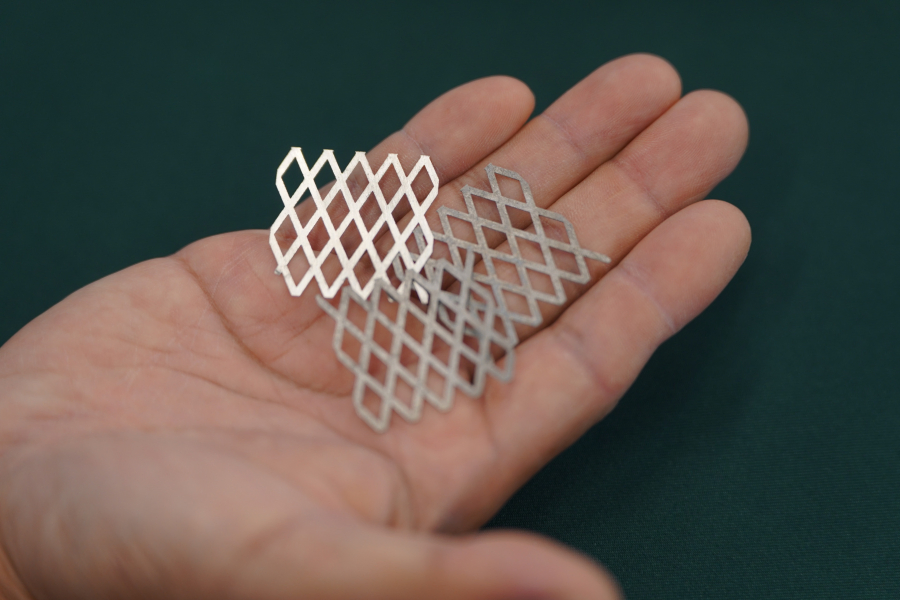

Stainless ‘Super Steel’ revolutionizes green hydrogen production from seawater

- A new stainless steel technology called SS-H2, developed at the University of Hong Kong, represents a major leap in creating cost-effective and corrosion-resistant materials for water electrolysis systems. It provides a sustainable and economically viable solution for producing green hydrogen which could transform green hydrogen production and advance the global transition to clean energy.

- The high cost and material limitations of current electrolysis systems have hindered widespread adoption of green hydrogen, produced by splitting water into hydrogen and oxygen using renewable electricity. Structural components in these systems, often made from gold- or platinum-coated titanium, contribute significantly to expenses.

- SS-H2 offers comparable corrosion resistance to titanium at a fraction of the cost and could cut material expenses by up to 40 times for a standard 10-megawatt proton exchange membrane (PEM) electrolysis system, positioned as a game-changer for industrial hydrogen production.

- The material can withstand chloride-rich conditions at ultra-high potentials of up to 1700 millivolts, even in saltwater environments, opening new possibilities for producing green hydrogen directly from seawater. The material's dual-passivation layers provide unprecedented resistance to corrosion, ensuring durability in harsh environments, reducing maintenance costs, and enhancing the overall efficiency of hydrogen production systems.

- The use of green hydrogen, enabled by cost-effective materials like SS-H2, spans several industrial applications, including ammonia production, oil refining, steelmaking, and methanol production, all supporting cleaner transportation and power generation.

- SS-H2 breaks through limitations in stainless steel's corrosion resistance, long reliant on chromium, with its dual-layer passivation mechanism. This achievement highlights the transformative potential of material science in addressing urgent global challenges.

- Professor Huang's team's dedication highlights the importance of scientific exploration, challenging established knowledge and pursuing unconventional ideas, propelling humanity toward a cleaner, greener future.

- The transition of SS-H2 from laboratory to industry is underway, with tons of material already produced. Large-scale applications aim to drive down costs and emissions, paving the way for a sustainable energy future.

- Companies such as Shell, Linde, and Bloom Energy are already integrating green hydrogen into their operations, and as industries adopt this innovative stainless steel, the potential to drive down costs and emissions grows, paving the way for a sustainable energy future.

Read Full Article

18 Likes

For uninterrupted reading, download the app