TechBullion

3d

75

Image Credit: TechBullion

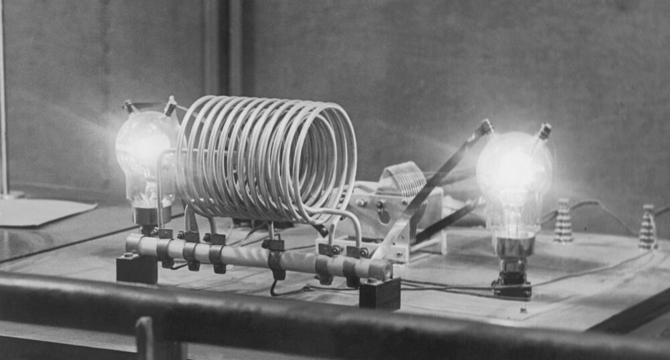

The Evolution of Coil Winding Machines: What’s New in 2025?

- The coil winding machine has evolved from manual labor-intensive machines to cutting-edge technologies integrated systems in 2025.

- From manual winding in the 19th century to CNC-based systems in the late 20th century, automation has continuously improved efficiency and precision in coil winding.

- In 2025, coil winding machines now incorporate AI algorithms for optimized winding patterns, real-time parameter adjustments, and predictive maintenance, reducing downtime and enhancing longevity.

- IoT connectivity allows for remote monitoring and control, contributing to synchronized factory ecosystems for increased productivity, safety, and quality in coil winding.

- Coil winding machines in 2025 feature advanced robotics, precision motors, and are capable of handling complex winding geometries for various industries, including aerospace and medical devices.

- Micro-winding machines have emerged to handle ultra-fine wire gauges, catering to industries like hearing aids and nano-sensors that demand miniature coils.

- The electric vehicle industry has driven growth in coil winding with high-speed, high-torque machines for efficient coil production, aided by automated quality inspection tools.

- Renewable energy systems rely on coil winding machines for larger coils, thicker wires, and composite materials for enhanced performance and longevity.

- 2025 sees the implementation of sustainable practices in coil winding machines, incorporating energy-efficient components, recycling processes, and closed-loop production systems.

- Modern coil winding machines feature user-friendly interfaces, modular designs for customization, and anticipate future innovations to meet evolving industry demands by embracing automation and digitization.

Read Full Article

4 Likes

For uninterrupted reading, download the app