Bioengineer

5d

57

Image Credit: Bioengineer

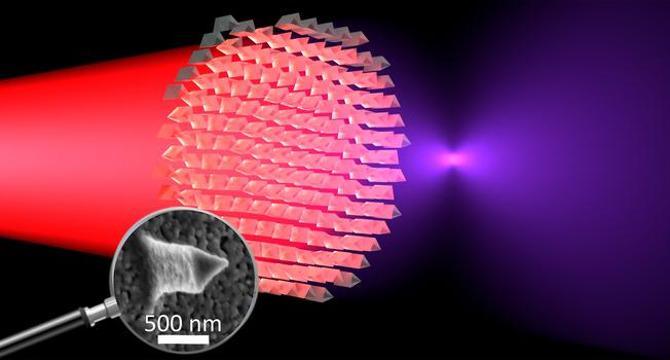

Breakthrough Ultra-Thin Lenses Enable Visualization of Infrared Light

- Metalenses, ultra-thin flat lenses made of metasurfaces, have revolutionized optics by allowing precise focusing of light in a compact form.

- Researchers at ETH Zurich have developed a novel method to create metalenses using lithium niobate, a material known for its nonlinear optical properties.

- The nanoimprinting technique devised by Professor Rachel Grange enables efficient and scalable fabrication of complex lithium niobate metasurfaces.

- Lithium niobate metalenses can focus infrared light sharply and convert it into visible light wavelengths with high efficiency.

- These metalenses offer opportunities in telecommunications, microscopy, and advanced sensing due to their wavelength-agile properties.

- In addition to optical applications, the security sector can benefit from the use of nanoscale metalenses as counterfeit deterrents.

- The integration of lithium niobate metalenses simplifies optical instruments, enabling new capabilities like infrared signal detection in standard camera systems.

- The scalability and cost-effectiveness of metalenses open doors for innovative optical devices in various fields, including semiconductor manufacturing.

- Continued development of metalenses could lead to ultra-compact optical systems with multiple functionalities in a single nanostructured layer.

- Collaboration between researchers, engineers, and industry partners is crucial for commercializing metalenses and unlocking their full potential.

Read Full Article

3 Likes

For uninterrupted reading, download the app