Physicsworld

1M

316

Image Credit: Physicsworld

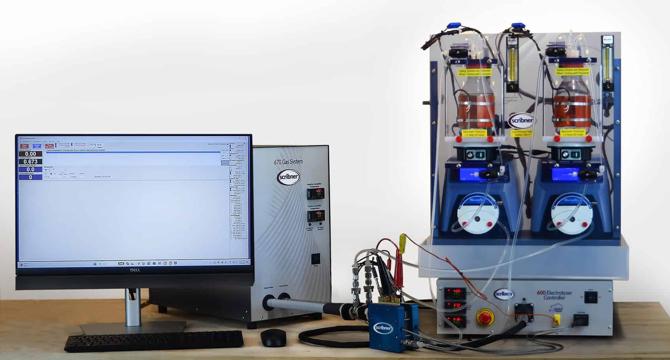

Electrolysis workstation incorporates mass spectrometry to accelerate carbon-dioxide reduction research

- The electrochemical reduction of carbon dioxide is an important industrial process with potential to capture and utilize carbon dioxide.

- Developing efficient electrochemical processes for carbon-dioxide reduction is crucial for R&D, involving catalyst and electrolyte optimization.

- Challenges in operating electrochemical systems include maintaining proper gas humidification and minimizing carbonate production.

- The 670 Electrolysis Workstation by Scribner offers a flexible and customizable system for testing materials and developing carbon-dioxide reduction systems.

- The workstation features gas diffusion electrodes, membranes for ion migration control, and a ±20 A and 5 V potentiostat for accurate operation.

- It is controlled by Scribner’s FlowCell™ software, providing full control, monitoring, and safety features for various experimental protocols.

- Gas handling units in the workstation supply humidified gas crucial for converting carbon dioxide to products like methane and syngas.

- The integration of mass spectrometry, such as Hiden Analytical's HPR-20, enables continuous gas analysis and optimization of electrochemical processes.

- Pulsed-mode operation in electrochemical cells helps minimize carbonate production, and real-time monitoring with mass spectrometry aids in optimizing gas production.

- Scribner is working on improving system time resolution and boosting the current capacity of the 670 Electrolysis Workstation for better research capabilities.

Read Full Article

19 Likes

For uninterrupted reading, download the app