Semiengineering

2d

78

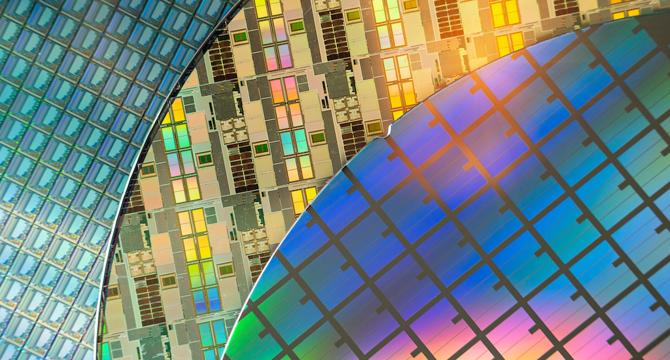

Image Credit: Semiengineering

Getting The Biggest ROI On Your Digital Twin

- The semiconductor industry has seen great investments from industry players and governments alike in digital twin technology, and there are many potential applications across the value chain.

- Digital twins are a virtual representation or model that is the real-time digital counterpart of a physical object or process.

- Developing digital twins in an industrial setting involves asking the right questions and ensuring consistently trustworthy results.

- It is important to determine the problem at hand and the outcome you seek, and whether you need a model that outputs results to make decisions, or do you need to visualise something?

- Infrastructure and supporting systems need to be in place to organise and distribute data in your processes and ensure the appropriate amount of time is spent ensuring initial data cleanliness and organisation, while also making sure that data is programmatically stored to continually feed the models.

- Clean data is the lifeblood of any viable model or digital twin, requiring data scientists to devote significant time to collecting, cleaning and organising data.

- Selecting a solution that completely handles the challenge of data management is important.

- Expert collaboration across processes, data and operations is necessary to reap the most rewards from digital twins.

Read Full Article

4 Likes

For uninterrupted reading, download the app