Physicsworld

1M

285

Image Credit: Physicsworld

Hydrogels rapidly switch from soft to hard to create smart medical bandage

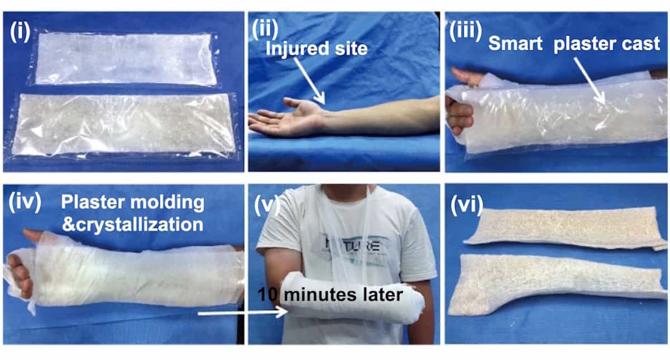

- Researchers at Zhejiang University in China have developed 3D-printed hydrogels that can switch between soft and hard states, enabling applications like smart medical bandages.

- This switchable composite is created by infusing supersaturated salt solution into polyacrylamide-based hydrogel structures, allowing for a rapid transition from soft to hard.

- The material's mechanical properties are enhanced through crystallization, with significant improvements in Young’s modulus and compression strength observed.

- The hydrogel can be easily returned to its soft state through heating and cooling, making it reusable for multiple cycles of switching.

- The research team demonstrated the application of this technology in creating a smart plaster cast for medical fixation, providing rapid support for injuries with fast crystallization.

- Compared to traditional plaster casts, the smart plaster cast hardens much faster, reaching higher yield strength and maintaining a safe temperature during the process.

- The smart plaster cast allows for easy imaging during the healing process, facilitating high-quality X-rays to monitor bone fractures.

- While the composite material shows high strength and modulus, researchers aim to enhance its toughness without compromising these properties for stronger and tougher materials.

- The study on this hydrogel technology is described in the International Journal of Extreme Manufacturing.

- The innovative hydrogel composites have the potential to revolutionize medical bandages and other applications requiring dynamic material properties.

Read Full Article

17 Likes

For uninterrupted reading, download the app