Bioengineer

2w

341

Image Credit: Bioengineer

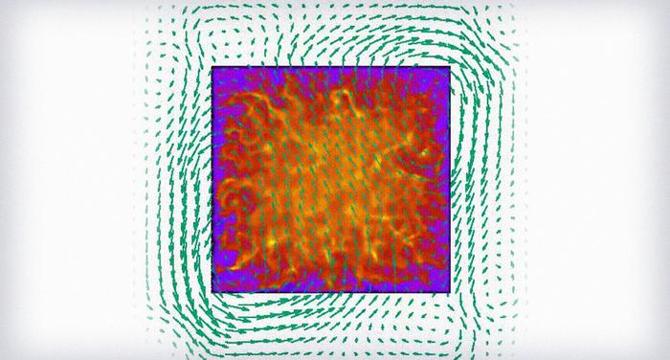

New Breakthrough Accelerates and Enhances Accuracy in Plasma Simulation for Computer Chip Manufacturing

- A recent breakthrough in plasma simulation methods has led to enhanced accuracy and computational efficiency in optimizing industrial applications, particularly in semiconductor manufacturing.

- A novel particle-in-cell code developed through a collaboration between the U.S. Department of Energy’s PPPL and Applied Materials Inc. improves stability and fidelity in simulating inductively coupled plasmas.

- This advanced simulation approach addresses the kinetic nature of plasma, offering detailed insights into particle interactions and electromagnetic forces for improved process optimization in microelectronics.

- Key to the success of the refined simulation is the accurate calculation of the solenoidal electric field, crucial for inductively coupled plasma generation and stability.

- The novel simulation method meticulously enforces energy conservation, ensuring trustworthy outputs and supporting decision-making in industrial contexts.

- The particle-in-cell methodology enables detailed observations of plasma characteristics, leading to improved control, uniformity, and precision in semiconductor fabrication processes.

- The collaborative research initiative exemplifies the role of public-private partnerships in driving technological advancements, with potential implications for various sectors relying on plasma technology.

- The progress in plasma simulation not only accelerates computational speed but also holds promise for scaling to larger plasma setups, offering significant economic and performance benefits in industrial applications.

- This advancement is expected to garner attention in sectors like semiconductor fabrication, where even slight improvements in plasma control can lead to substantial benefits.

- The breakthrough in plasma simulation represents a significant stride in industrial process innovation, supported by a strategic investment from the U.S. Department of Energy.

- The application of detailed computational modeling in understanding plasma behavior opens new possibilities for semiconductor device fabrication and future technological advancements.

Read Full Article

20 Likes

For uninterrupted reading, download the app