Knowridge

1M

125

Image Credit: Knowridge

New laser-printed circuit technology makes electronics greener and more flexible

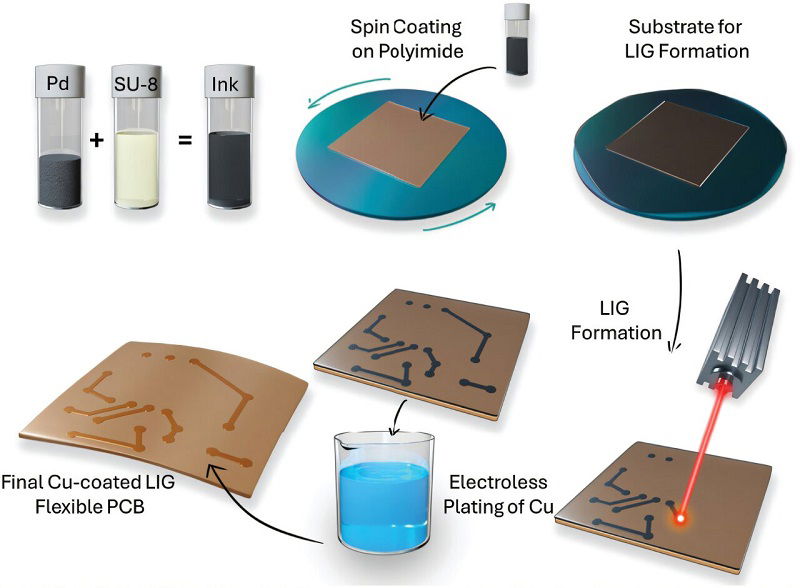

- Researchers at Boise State University have developed a new method to create flexible electronic circuits using laser-induced graphene (LIG) without the use of harmful chemicals.

- The new technology involves mixing palladium nanoparticles into a soft plastic material, which when exposed to a laser, forms a network of copper wires on a flexible circuit for building hybrid devices.

- These copper connections, known as interconnects, can be utilized in wearable devices and flexible electronics, offering benefits like space-saving, lightweight design, and durability when bent.

- The innovation in making printed circuit boards (PCBs) using this method is more environmentally friendly, cost-effective, and efficient compared to traditional PCB manufacturing processes, opening doors for a greener approach in electronics production.

Read Full Article

7 Likes

For uninterrupted reading, download the app