Scrum

1M

223

Image Credit: Scrum

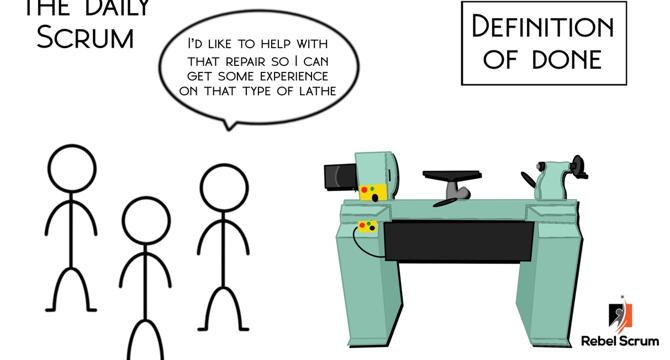

Scrum in a Machine Shop

- Maintenance team at Argus, responsible for 60 CNC machines, faced challenges with workload management and process inconsistencies.

- To address these challenges, Maintenance Manager Brayden Yundt introduced Scrum framework, implementing a one-week sprint cycle and a refining meeting to prioritize projects.

- The team found benefits in the Daily Scrum and the team's ownership of the Definition of Done, improving task alignment, balancing planned and unplanned work, and setting standards for repairs.

- Scrum-based maintenance system has resulted in a more accountable, communicative, and efficient team, leading to plans of expanding the approach to other locations.

Read Full Article

13 Likes

For uninterrupted reading, download the app